Industrial application specific training, to prepare you for industrial projects.

Covers an end-to-end hardware development & programming process for creating an industrial IoT device from scratch, with a step by step approach.

Covers several industrial interfaces for process automation & wireless modules, for remote monitoring & controlling.

Shows how to connect the hardware to the internet to make an Internet Of Things device.

Uses Eagle software for PCB designing & Arduino IDE for programing the hardware

This is application-oriented training. You will learn things from an industrial-application perspective.

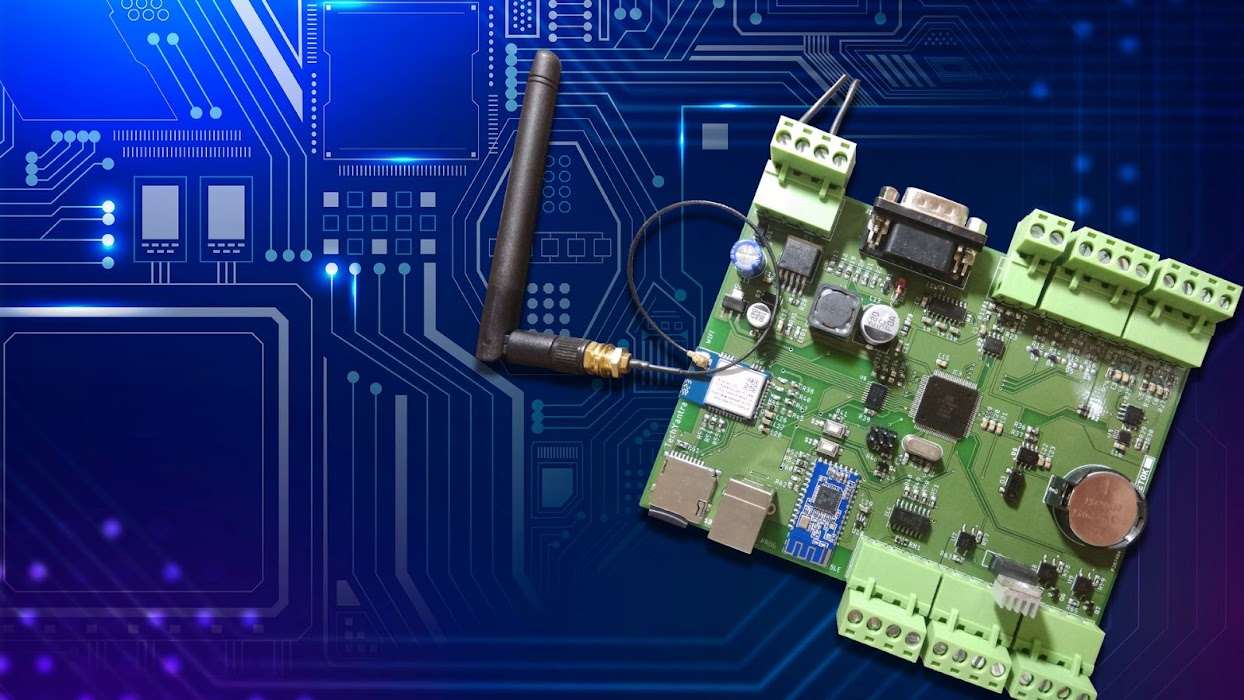

We will be building hardware for remote process monitoring, controlling & data logging. Everything that’s required in the process is covered in a detailed and step-by-step manner. The primary focus is on designing & programming a PCB for industrial applications.

We will be building a customized Arduino Mega board that can be programmed using the Arduino IDE. We will cover several industrial interfaces, their circuit designing, interfacing with the microcontroller, and programing.

By the end of the training, you will have covered end-to-end hardware development & programming approach for industrial process automation. You will be confident and ready for different industrial automation-related projects.

Circuit Design

PCB Design

Hardware testing

Industrial interfaces

Hardware cloud integration

Remote monitoring, controlling & data logging

Application specific programing

Students, professionals and hobbyists who want to build a commercial/engineering project around IOT or industrial automation.

People who want to learn how industrial automation works, and how processes are remotely monitored & controlled.

People who want to learn the most commonly used industrial interfaces and hardware design for industrial applications.

People who wants to step up in the embedded hardware field

People who want knowledge to get an internship or a job in the embedded hardware field.

Overall you will learn to design a hardware for different blocks available & will develop a sense of designing a hardware for a specific application

Industrial electronics circuit design & PCB design using eagle software

Fundamental circuit design concepts

Atmega256 (Used in Arduino Mega) Microcontroller based system design

Power supply design based on SMPS & Linear regulator

Hardware designing of industrial interfaces : RS485, RS232, 0-10v Digital Input, 0-10v Analog Input, 4-20 mA.

Hardware design of wireless communication modules : WiFi & Bluetooth

Hardware design of SD Card interface & Real-time clock

Hardware design of DC motor speed controller, relay driver

Hardware design to control AC appliance

Working with Modules : USBASP, USB to TTL converter, Logic analyzer

PCB ordering process

Components ordering process

Hardware Testing process

Purpose of every single component used on hardware

Arduino Mega based customized hardware

Overall you will learn to write a firmware for different blocks available on hardware & will develop a sense of how to write a firmware for a specific application

Basic Arduino programming concepts

How to use Arduino programming to build a dedicated application

Programming industrial interfaces : RS485, RS232, 0-10v Digital Input, 0-10v Analog Input, 4-20 mA.

Programing wireless communication modules : WiFi & Bluetooth

Programing SD Card interface & Real-time clock

Programing DC motor speed controller & relay driver

Programing to control AC appliance

How to integrate hardware with cloud using Wi-Fi

How to integrate hardware with cell phone using bluetooth

Automation in the industry, across all domains, is increasing every day. So, the demand for the people responsible for automation is also going up (Hardware designers, Firmware developers).

The manufacturing companies want to optimize the process to make it fast and error-free. So, they need people who can help them automate the process.

If you enjoy building an electronics product & want to work in electronics product development companies, then this training will help you reach there.

Whether it's automotive, media, petrochemical, consumer or medical industry automation is everywhere. If you enjoy automating the process & designing a system based on a microcontroller & microprocessor excites you, then this training is for you.

Some of the examples of industrial automation devices are

PLC - Programmable logic controller

Industrial Data Logger & telematics devices

The total installed base of IOT devices worldwide is projected to be around 30 billion units by 2025. The demand for hardware designers and firmware developers is increasing day by day.

Knowledge of electronics basic components is preferable but not mandatory. All the software/tools that you need for the training would be shared with you during the training as and when you need it.

Testimonials

FAQ

Automation means making the process automatic to eliminate human intervention. Industry can be automotive, consumer, aerospace, media, manufacturing, etc.

Following are the reasons for industrial automation,

Examples of Industrial process automation

We created this training considering four different applications & most of the hardware you will see in the industry will be around these applications.

The purpose was to train an individual so that, whenever they have a project requirement around the application, as mentioned earlier, they should be capable of designing the hardware considering the application requirement.

In the first question, we have already discussed industrial automation. Similarly, process automation is nothing but making processes automatic. To do this, we design electronics systems.

To make the process automatic, we generally need external input, or the system needs to generate some output to control external devices.

The external input can be digital or analog, and an external sensor or instrument can generate this input. So, to understand the information or to read the input, we need some circuits.

Examples of external inputs.

In the same way, we need some circuits to generate some output or to trigger an external process (again, which can be analog or digital).

Examples of system-generated outputs.

So, overall in process automation, we need to design a hardware.

So, in this training, we will deal with the above three points and the design process using a microcontroller & external circuit.

As the name indicates, data + logger. It means a device or hardware which is responsible for storing the data. Now the question comes, which data and why do we have to store the data?

Let's answer the first question. The devices deployed in the field can collect different types of data.

Now let's understand why we have to store the data. There could be multiple reasons why we need to keep the data.

The overall data logger is a kind of hardware that stores the data for future use.

We need interfaces to read external input and generate output to automate the process. Also, we need some communication interfaces to communicate with the external machine or hardware.

Following are the interfaces we are covering in this training.

Remote monitoring means monitoring (observing) the process remotely (From a long distance), and similarly, remote controlling means controlling the process remotely without being physically present in the field.

The purpose of most IoT devices is the same. They are either used for remote monitoring or remote control.

Example.

Remote monitoring.

Remote controlling.

So, in this training, we will see how to monitor & control different processes using wired medium (RS232 & RS485) and wireless medium (WiFi & Bluetooth).

There is a reason why we built hardware around the Arduino platform.

We created training with the purpose of showing the entire development process, which includes both hardware development & firmware development.

Generally, most hardware designers understand how to design hardware but don't know how to program the hardware to make a specific section work.

That's why covering the programming process as simple as possible was essential to give a comprehensive insight into how hardware and firmware work together.

Arduino is simple; you don't have to dive deep into programming to write code for a specific application. So, having a superficial understanding of programming is enough to create an application, which is very important from a beginner's point of view.

So, we wanted to show how to program different sections available on hardware without getting too involved in the programming complexity & Arduino was the perfect solution. That's why creating hardware compatible with the Arduino ecosystem was essential.

The IC used on the hardware is the same IC that is present on the Arduino Mega board (ATMEGA256).

Knowledge of electronics basic components is preferable but not mandatory. All the software/tools that you need for the training would be shared with you during the training as and when you need it.

Our website has a dedicated FAQ page; please check all the available questions. If you still need further assistance, you can always reach us at [email protected], and we will be glad to help you.